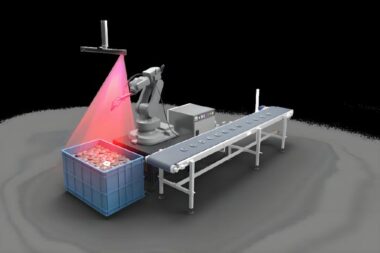

Usage scenario

- Suitable for all kinds of parts manufacturers in the production process of gluing process testing

Product characteristics

- The self-developed algorithm is not limited or dependent on the specified hardware alone, and is suitable for various field environments. The measurement results are accurate and reliable, and are not subject to subjective influence.

- Flexible use of a variety of methods, using the workpiece coating after the completion of the overall detection or workpiece coating process detection.

- Cover the glue to be detected without dead corners, support three basic color switching and different exposure and parameter Settings of glue to adapt to different detection scenarios

- Support manual teaching, automatic auxiliary teaching, image replacement teaching, improve efficiency Support binding VIN code with test results, automatic export of data statistics and reports Support real-time gluing test results uploaded to the group control system for traceability storage

- With data recording and statistics function defect function, and can use supporting hardware to enhance product uniqueness, users can trace at any time.

The data pool provides reference for the subsequent production process improvement.

info@JHL-guangdong.com

info@JHL-guangdong.com